Vintage bikes are a disease. Long time motorcycle riders regularly become infected with a desire for a vintage machine. There are many strains to this disorder: old school British bikes, twin shock motocrossers, two-stroke street bikes, classic European rides, antique American iron, and universal Japanese motorcycles. There are some common technical issues to these old machines whatever type your dealing with.

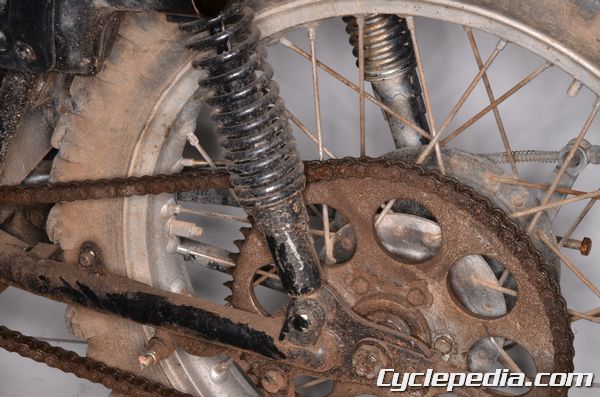

Often the first step in dealing with a vintage machine is making it mobile. Not so much in being able to ride it down the road, but just being able to roll it onto a trailer or from one side of the shop to the other is a good start. Air up the tires if possible. If the drive chain is rusted, or there is a mechanical engine problem preventing the rear wheel from turning, remove or cut the chain off to get the rear wheel turning so the bike can be moved easily.

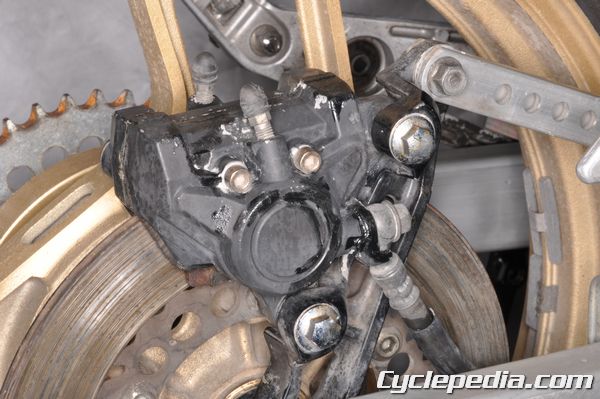

Almost all old bikes have brake problems. Old brake fluid will crystallize behind the seals and seize the pistons against the discs. Seized disc brake calipers can be temporarily freed up by smacking the caliper with a rubber mallet. The hydraulic brake system will need to be dissembled and cleaned up. All of the old gunk on the pistons and behind the caliper seals needs to be removed prior to installing new seals and brake fluid. The master cylinder will also require similar attention.

Disk brake are futuristic compared to many vintage bikes. Drum brakes have their own issues. Old crusty drum brakes can seize up too. Disconnect the cable or rod and manually move the cam lever to try and free up a drum brake. The old drum brake drums will need to be cleaned up and inspected for wear and damage. The old brake cables will probably need to be replaced too. Note old brake shoes often contain asbestos so take appropriate safety precautions when cleaning up old brake dust and handling brake shoes. When inspecting the drum brakes note the position of the cam lever. Some previous owner or shade tree mechanic may have changed the position of the cam lever on the brake cam looking for more brake performance. Make sure the lever is aligned correctly in the factory position.

Take the time to make a detailed visual inspection of the bike. Look for cracked welds and suspect homemade modifications and repairs. Take note of any aftermarket or adapted parts. If the bike has an aftermarket carburetor it will need to be identified so any rebuild parts can be ordered to fit.

Inspect the fuel system starting with the fuel tank. Old fuel tanks are often rusted on the inside. Use a suitable chemical cleaning method to remove the rust from the inside of the tank, and then seal the tank with a fuel tank sealer. Check and replace fuel filters as necessary. Inspect the fuel valve and fuel lines. Old fuel valves may not function correctly anymore and fuel lines often deteriorate over time.

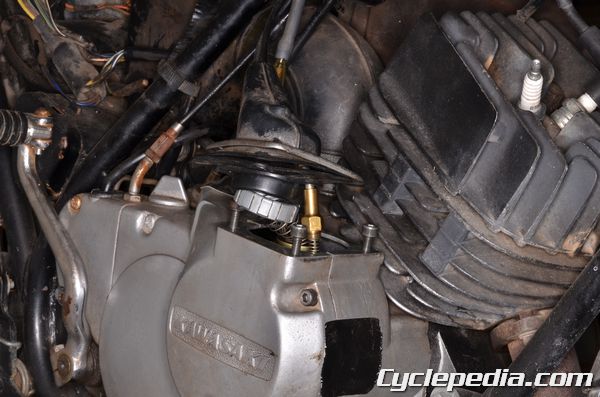

Consider anything rubber to be suspect- tires dry rot, hoses crack, seals fail. Be prepared to replace any rubber component that needs to be manipulated during service work. Leaky crank seals are the bane of old two-stroke engines. Perform a pressure leak down test on the engine to make sure the bottom end of a 2-stroke is air tight. A two stroke engine should be able to hold 6 to 9 psi for 5 to 10 minutes without losing any pressure. Find the leak source before disassembly to identify the faulty component. Perform another leak down test after a rebuild to make sure an air leak won’t ruin your fresh motor.

Repair and parts manuals are great tools for all motorcycles especially old machines that need work. Repairmanual.com is a great source for vintage bike service information. Take photos of the components as they are disassembled to supplement the repair manual. In some cases the photos might be the only documentation available when reassembling the vehicle. Have a skeptical mind when dealing with an old bike as previous owners or technicians may not have always assembled pieces correctly.

Leave a Reply

You must be logged in to post a comment.