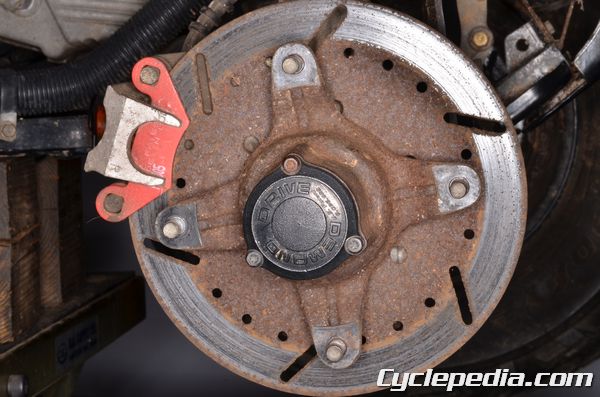

Polaris 4×4 models use a Hilliard clutch to engage power to the front wheels. The newer models house the Hilliard system in a central front gearcase that from the outside looks similar to most 4x4s. The early 2004 and older models have an individual Hilliard clutch in each front wheel hub. These hubs are a critical part of the drive system and must be maintained.

The hub fluid must be changed on a regular basis according to the periodic maintenance chart in the service manual. It must be drained and replaced whenever the hub is removed. Also, the hub needs to be drained and flushed with oil to remove moisture if the hub has been submerged in water or otherwise contaminated. Do not let the hubs run dry as the hub fluid provides lubrication for the front wheel bearings.

Support the vehicle with a suitable stand or jack and remove the front wheels for better access to the hubs. Picture the hub as a clock face and position the hub fluid plug straight up at the 12 o’clock position. Remove the fluid plug from the hub. Rotate hub forward or back until the fluid plug hole reaches the 4 or 8 o’clock position. If the fluid level is correct the fluid should dribble out of the hole. Turn the hole to the 6 o’clock position or remove the cap to drain the fluid. Position the hole at the 4 or 8 o’clock position when filling to set the level correctly.

Look over the seals if the fluid level is low. The hub fluid can leak from a faulty cap O-ring on the outside of the hub, hub seal on the back side of the hub, or the strut hub seal on the strut housing where the CV axle enters the strut housing. Replace the seals as necessary. Do not hesitate to replace them all. Apply a light coat of grease to the new seals, but do not grease wheel bearings or allow the grease to contaminate the Hilliard clutch components.

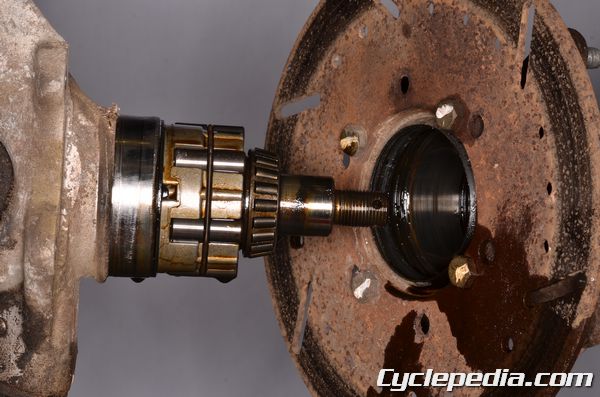

Clean and inspect the Hilliard clutch components if the hub is removed. Replace the retaining spring with a new item if it is in poor condition or longer than the specified length. Use the Polaris special spring installer tool to install the spring with minimal stretching. Make sure to replace the spring with the proper component as the springs differ over the years, and while they may look the same the spring tension is not. A dangerous situation can be created if the spring is faulty or the incorrect component is installed, as the Hilliard clutch may inadvertently engage at high speed.

Check the action of the Hilliard clutch by hand before installing it. Hold the roller cage and rotate the inner cam. The rollers should be forced out by the cam, and when the roller cage is released the rollers should return to their resting position.

Inspect the seal sleeve (outer pole) to inner pole clearance in multiple locations with a straight edge and feeler gauge. The seal sleeve must sit 0 ~ 0.025 mm above the inner pole. This is especially important if the coil and seal sleeve are being replaced with new items. Adjust the seal sleeve position so the pole clearance is correct.

Lubricate the wheel bearings and Hilliard clutch assembly with Polaris Demand Drive Hub Fluid or other specified fluid. Assemble the hub and tighten the fasteners to specification. Position the fluid plug hole at the 4 or 8 o’clock position and fill the hub fluid until it reaches the plug hole. Install the hub fluid plug and tighten it securely. Test ride the vehicle and check for hub fluid leaks.

If you need a service manual for your Polaris check out the Cyclepedia online manuals: https://www.cyclepedia.com/online-manuals/polaris-atv-online-repair-manuals/ or get a print manual here: https://www.repairmanual.com/

Leave a Reply

You must be logged in to post a comment.