It’s spring time and all those motorcycles that sat out the winter are retuning to service. This is a prime time for the the fork seals to start leaking. A leaky motorcycle fork seal is more than just an eyesore. A loss of fork oil will at best degrade the damping performance and cause a failed inspection. At worst the fork oil can coat the front brake disc and tire leading to an unsafe motorcycle.

Replacing fork seals is a common job that has been with us for as many decades as the damping rod fork. All damping rod forks are essentially serviced the same way. The service becomes less straight forward when the level of suspension technology is more advanced.

Before starting a fork seal service take some time to make the proper preparation. The best place to start is a quality service manual that will have the factory specifications, procedures, and special tool requirements. Reading through the procedure before the job is started will help you make a better estimate for the customer and complete the job in less time.

The most common specifications you will need are oil volume, oil level, oil type, and torque specs. It is also good to know the service limits for the related components like fork spring free length. Note any special procedures, such as oil bleeding, to make sure the rebuilt fork performs as it was intended from the factory.

Having the necessary special tools to complete the job is vital. Replacing fork seals doesn’t take that long, even on complex forks, unless you realize mid-course you don’t have the right tool for the job. Now your stuck with having to wait for a special tool in the mail, or spending your time trying to make something work while your customer is waiting.

Many forks require a special tool to remove the cap.

The damping chamber might need its own special tool on some designs like the Yamaha YZ450F.

Sportbike forks often require a spring compressor tool like this item from Traxxion Dynamics. This tool will work on many different sportbike forks.

A very common fork tool is a damper holder. This will keep the damper from turning as the bottom bolt is loosened or tightened. Make sure to have the correct tool for the specific fork as there are several different types.

One of the most basic and handy tools for fork work is a fork oil level gauge. This will allow you to quickly and accurately set the oil level.

A set of quality fork seal drivers in common sizes is a must.

In addition to special tools there will be a need for additional parts beyond just the basic seals. Sealing washers and O-rings often need to be replaced anytime the fork is disassembled.

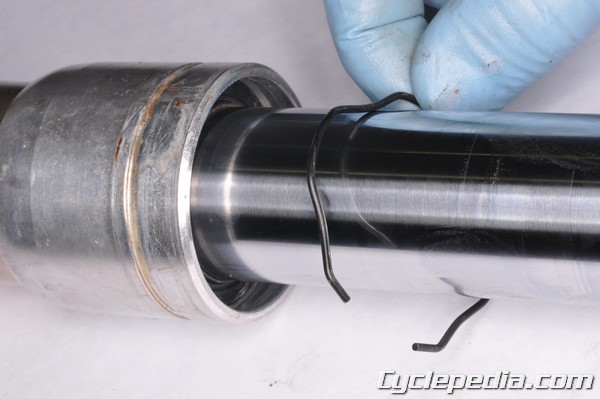

Usually the the stopper ring for the fork oil seal is not included in a fork seal kit. Sometimes this clip cannot be reused. This often occurs on “Right Side Up,” forks where the outer fork tube is on the bottom. This common type of fork is susceptible to catching water between the dust and oil seals. The water will rust out the stopper ring.

Changing the fork bushings at the same time as the fork seals is a great way to help the customer. You are already there, and installing new bushings takes little more time than putting the old ones back in. If the customer complains of a clunky feel to the front suspension stroke the bushings may be past their prime. Most bushings have a built in wear indicator. If the Teflon coating has worn off more than the specified amount (usually 75%) they need to go.

If you service motorcycles you will replace fork seals. Being prepared with specifications, procedures, and special tools will make this common job a breeze.

Leave a Reply

You must be logged in to post a comment.